The Kobe University start-up Photo-on-Demand Chemical Co. Ltd. demonstrated that it can produce methane from sewage to refine it into pharmaceutical raw materials and other useful chemicals. For this, TSUDA Akihiko, the CEO and associate professor at the Graduate School of Science, and his team have developed a “photoproduction” method that produces such chemicals by shining light on methane and chlorine, etc. The company was established in April 2024 and began demonstration tests at a sewage treatment plant of Kobe City in September. We asked Tsuda about the background to the research, which also promotes decarbonization policies known as “green transformation” (GX) in Japan, and future developments.

What made you start research on photoproduction?

Tsuda:

The initial trigger was when I thought about how to dispose of chloroform used in experiments during my time in graduate school. As chloroform is not easily flammable, it had to be incinerated using twice the amount of kerosene, which I felt had a significant environmental impact.

It was known that there was a method of decomposing chloroform by exposing it to light. However, as the reaction was difficult to induce, only a small amount of chloroform could be decomposed in this way, and it was considered not worth the effort. It was around 2008 that I started research to see if it would be possible to decompose large amounts.

As a researcher, you only get one chance in life, so I had a strong desire to do research that could be put to practical use and benefit society at large.

The “photo-on-demand organic synthesis method“ was born amidst headwinds

How did the research progress?

Tsuda:

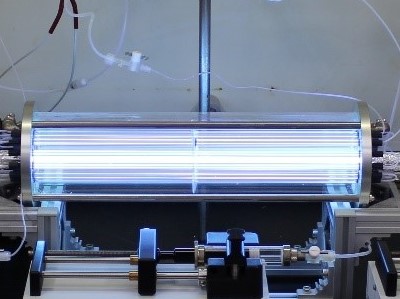

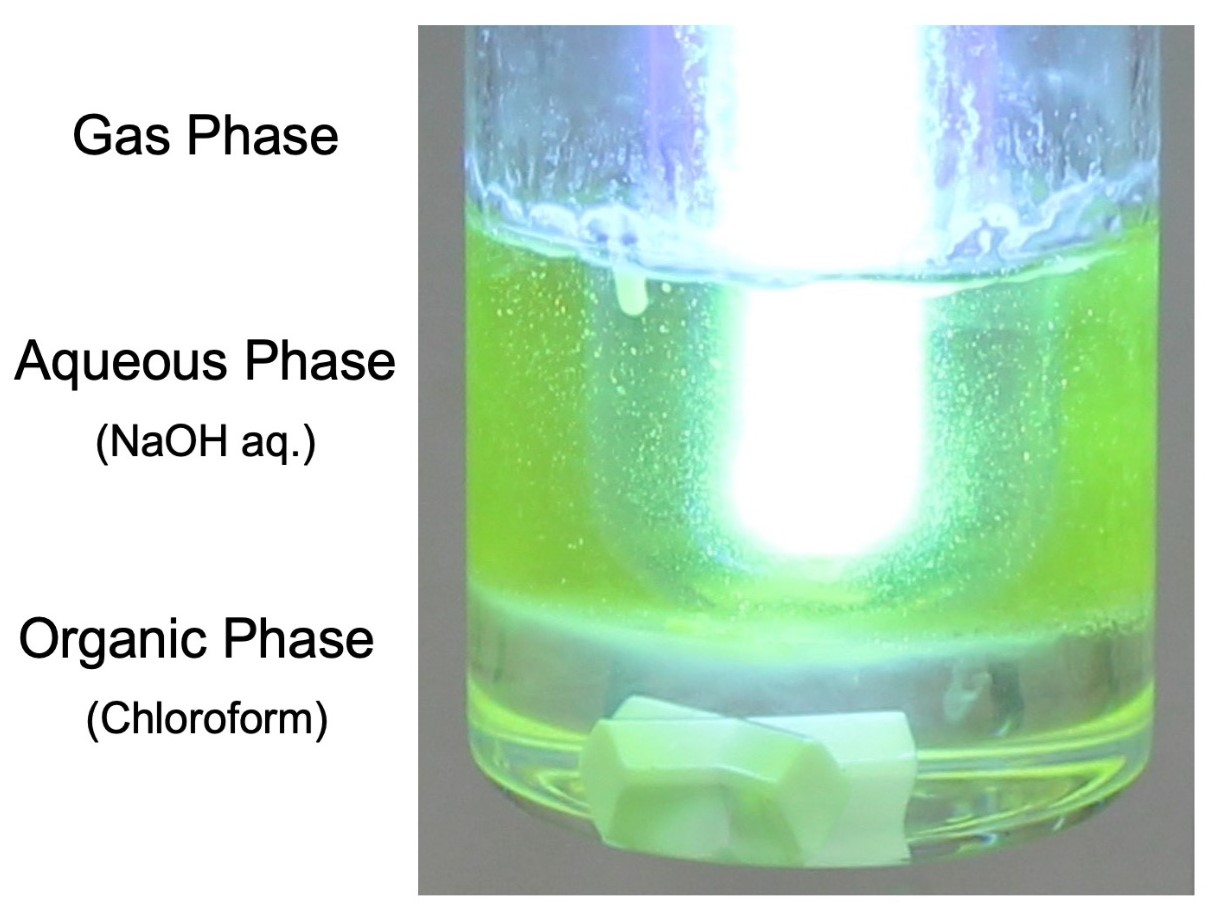

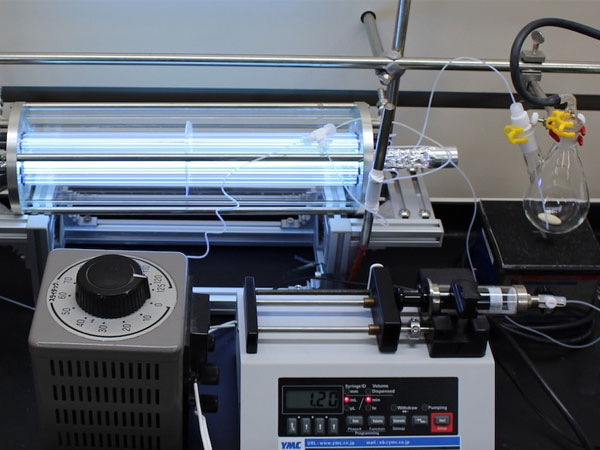

During our research, we discovered that chloroform can be decomposed very efficiently when exposed to intense ultraviolet light. Furthermore, a distinctive feature of our research was that we not only decomposed chloroform but also considered the chemical substance phosgene that is produced in the decomposition process.

Phosgene is a very useful substance and is widely used as a raw material for polyurethane. However, it is extremely toxic and storing it as such poses significant dangers. Therefore, we came up with the idea of instantly causing a chemical reaction with the phosgene produced during decomposition, transforming it into a useful compound.

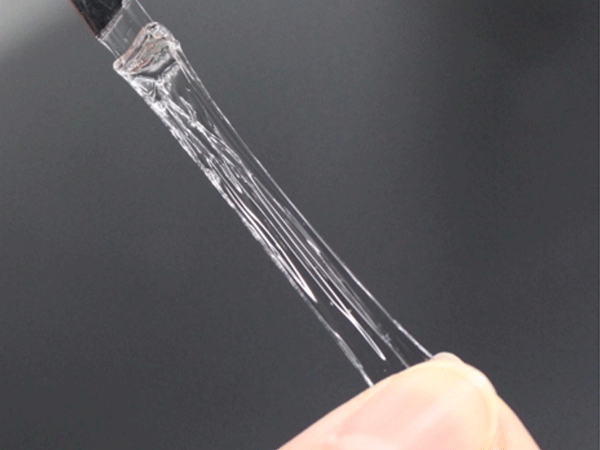

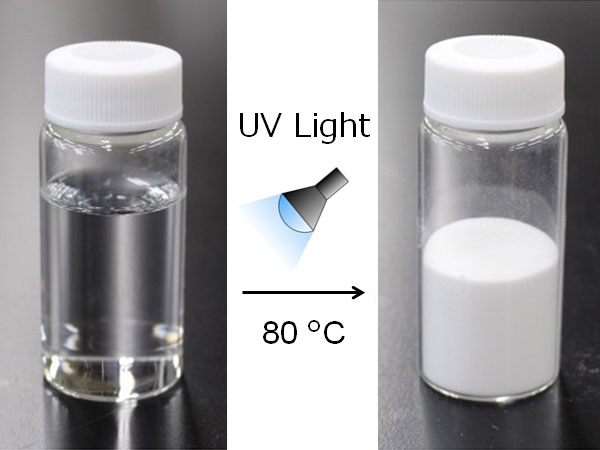

The series of methods we developed is the “photo-on-demand organic synthesis method,” a world-first. Using this synthesis method, phosgene disappears in an instant, leaving only the necessary compounds. It is also very safe, as phosgene production stops when light irradiation is stopped.

It took more than 10 years to bring this research to the public. One of the reasons behind this is the dangerous nature of phosgene. Phosgene can be repurposed as a weapon in one step, so we refrained from publishing papers until we could confirm the safety of the technology we had developed. Also, for the first few years, there was almost no one to evaluate our research. Only the staff in charge of industry-academia collaboration at Kobe University scrambled to realize joint research with companies, and this support led to the current results.

Collaboration with Kobe City to utilize methane from sewage treatment plants to promote the green transformation

In a demonstration experiment started this year, the system uses methane as a raw material to produce phosgene. How does this connect with your previous research?

Tsuda:

We had been conducting joint research with companies since around 2016 on methods using chloroform as a raw material. However, the scale of production required by large companies is very large and there were various challenges when it came to practical application.

Therefore, from 2023, we started focusing on methane as an alternative raw material. Of the greenhouse gas emissions that cause global warming, carbon dioxide accounts for 76%, followed by methane (18%). In the past, methane was considered difficult to convert into chemicals and, compared to carbon dioxide, there has been little research into its utilization as a chemical raw material.

However, I came up with the idea that by combining methane, chlorine and oxygen, and using our photo-on-demand organic synthesis method, it might be possible to produce phosgene. It was an idea born out of years of accumulated research. The use of methane is also groundbreaking from the perspective of promoting the green transformation. We built the system and, in consultation with the intellectual property staff at Kobe University, applied for a patent.

The idea to utilize methane from sewage treatment plants came about because whenever I passed by the treatment plant in Higashinada Ward, Kobe City, I was curious about the large tanks. When I looked into it, I found out that the methane generated in the sewage treatment process was being used as biogas. And when I consulted Kobe University Innovation Co. Ltd. (KUI), which supports ventures within Kobe University, about collaborating with Kobe City, the discussions proceeded with a bang, with preparations for the experiment starting in April 2024.

Why did you set up a company?

Tsuda:

The establishment of the company is closely related to the start of methane utilization. Based on past experiences, it can be faster to achieve practical application as a start-up, producing high-value-added chemicals on a small to medium scale, instead of aiming for large-scale production in collaboration with existing companies.

In fact, the chemicals produced from phosgene are diverse, including pharmaceutical raw materials, agrochemical raw materials, adhesives and flavorings, which allows for a value-added business model even with small-volume production. In addition, the global market for the production of chemicals made from phosgene is said to be worth several tens of trillions of yen, so the market is huge.

The keys to practical application: simplicity, low cost and safety

What further expansion of the demonstration at the sewage treatment plant can be expected in the future?

Tsuda:

Since sewage treatment plants are located nationwide, the demonstration experiment in Kobe holds significant importance in terms of future developments. It means that we envision a future where sewage treatment plants become factories for chemical production.

As this research was born in Kobe, we first aim to establish Kobe as a hub for photoproduction. In addition to the Higashinada treatment plant where the demonstration experiment is being conducted, we are hoping to expand to other treatment plants utilizing biogas. Kobe University students are involved in the demonstration experiment, and so the project is also extremely beneficial from an educational point of view.

We are also advancing our collaboration with the city of Osaka. Our company was selected as a recipient of the second phase of the “KIDOU” program, in which the Osaka Business Development Agency provides funding support to start-ups, and this was the catalyst for our company to take off. We want to give back to Osaka and the Kansai region.

Could you share your outlook as a start-up?

Tsuda:

Our research is the world’s first initiative to upcycle waste into raw materials for chemicals. Waste is not limited to sewage; various materials such as livestock manure and food waste can also be utilized. When explaining the company’s business in simple terms, we say, “a company that makes medicine from poo.”

When promoting practical applications, it is crucial that the system is simple, does not incur high cost and, moreover, can be used safely for everyone.

As I mentioned earlier about the dangers of phosgene, we must always be aware that innovative inventions can be misused. To prevent misuse, I believe it is essential to keep society informed. It is necessary for society as a whole to monitor our research outcomes to ensure they enrich people’s lives and are used safely.

The system for producing chemicals from methane has attracted enquiries from a number of companies both domestically and internationally. Recently, we signed a joint research agreement with DKS Co. Ltd. in Kyoto. In relation to this series of studies, we have acquired and filed approximately 40 patents, and anticipate that this number will exceed 100 in the future.

I believe that in the next year or two, we will see significant progress towards practical application. As a start-up from Kobe University, we want to further advance initiatives that benefit society.

Resume

| March 1997 | Graduated from the Faculty of Engineering, Shinshu University |

| March 1999 | Completed the master’s program at the Graduate School of Engineering, Osaka University |

| March 2002 | Completed the doctoral program at the Graduate School of Science, Kyoto University |

| April 2002 | Research associate, Graduate School of Engineering, the University of Tokyo |

| April 2007 | Assistant professor, Graduate School of Engineering, the University of Tokyo |

| April 2008 | Associate professor, Graduate School of Science, Kobe University |